The global race to build AI infrastructure has collided with an inconvenient truth: the grid cannot keep up. Data centre electricity consumption is projected to double to 800–1,000 TWh by 2030, and gas turbines have re-emerged as the critical bridge between ambition and megawatts. Nowhere is that bridge shorter — or more strategically aligned — than in the Middle East.

Why It Matters Now

The International Gas Union's 2025 Gas for Data Centres report projects that gas-fired generation for data centres could reach 30 billion cubic metres of incremental supply by 2030 — and nearly double to 60 bcm by 2035. About 30% of new data centre sites globally are expected to rely on onsite power generation, a model known as behind-the-meter (BTM).

In the United States, the urgency is already visible. Meta's 5 GW Hyperion project in Louisiana is being built around H-class natural gas turbines. Oracle and OpenAI's Stargate project in Texas is deploying gas turbines from GE Vernova and Solar Turbines for onsite power. GE Vernova itself expects to end 2025 with an 80 GW gas turbine backlog stretching into 2029, with turbine reservations likely sold out through 2030.

The problem? Lead times for popular aeroderivative models like the GE LM6000 or Siemens SGT-A35 now stretch three to five years. Demand is outstripping manufacturing capacity worldwide.

This is where the Gulf has a structural advantage that few regions can match.

The Gulf's Built-In Power Advantage

Middle East data centre capacity is projected to triple from 1 GW in 2025 to 3.3 GW within five years, according to PwC. The UAE's Stargate UAE project alone envisions a 5 GW campus. Saudi Arabia's HUMAIN initiative targets 1.9 GW by 2030, scaling to 6.6 GW by 2034. Qatar has committed $2.5 billion to AI projects under its Digital Agenda 2030.

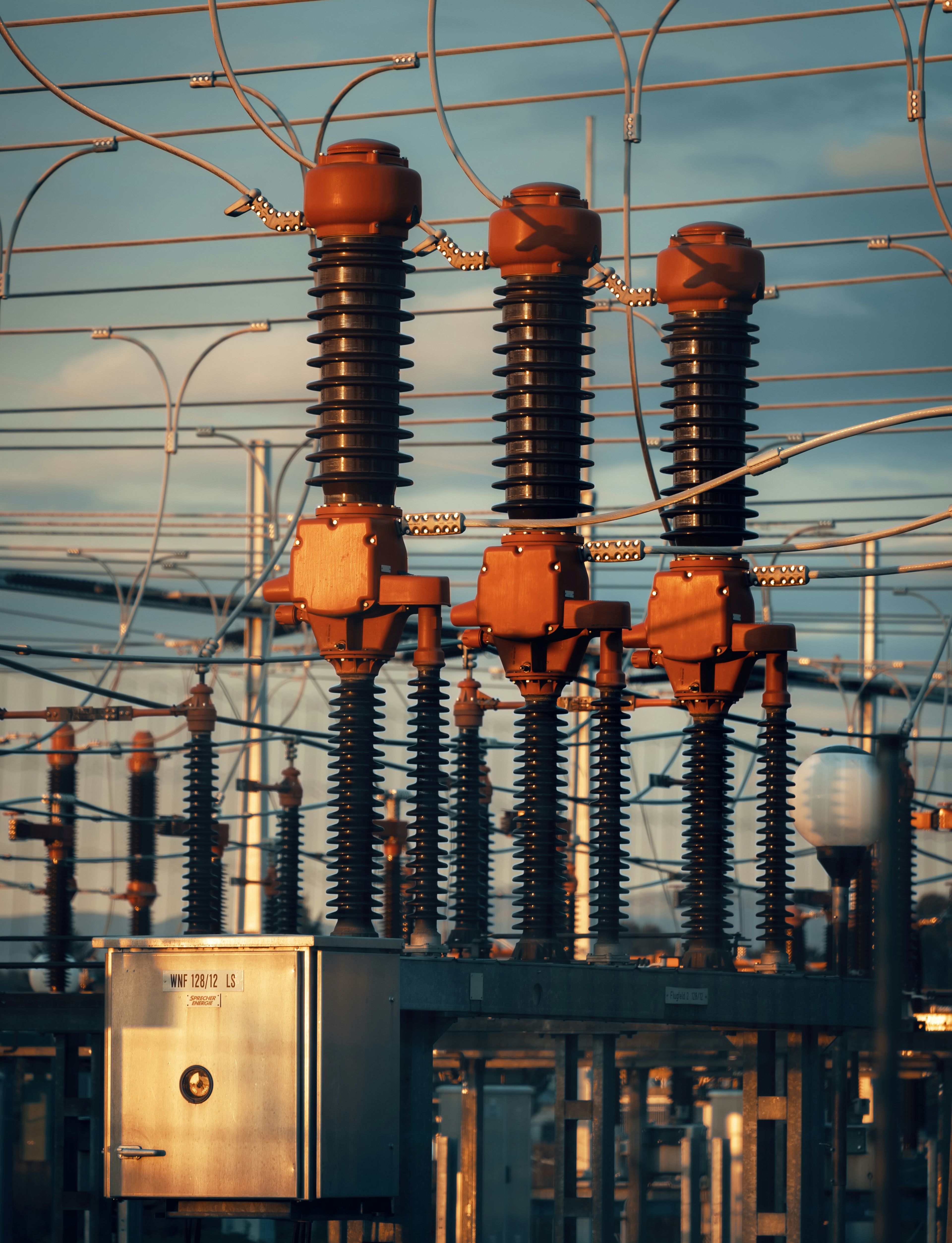

What sets the Gulf apart from Virginia or Frankfurt is not just capital — it is gas. Natural gas supplies over 95% of Qatar's electricity generation. Electricity tariffs across Saudi Arabia and the UAE run between $0.05 and $0.06 per kWh, well below the US average. The region already operates some of the world's most advanced combined-cycle gas turbine (CCGT) infrastructure, with thermal efficiencies above 60%.

Qatar's recently awarded Facility E IWPP — a 2.4 GW project powered by Mitsubishi Power's hydrogen-ready M701JAC gas turbines — represents roughly 20% of the nation's grid capacity. This is not speculative planning. It is turbines on order, EPC contracts signed, and Samsung C&T mobilising as contractor.

For hyperscale operators evaluating GCC locations, the equation is straightforward: abundant gas, existing turbine expertise, competitive tariffs, and sovereign-backed capital.

From Jet Engines to Server Racks

One of the more striking developments is the convergence of aerospace and data centre engineering. Companies like ProEnergy and FTAI Aviation are converting retired aircraft engines — including the CF6-80C2 and CFM56 — into aeroderivative gas turbines purpose-built for data centre power. FTAI Power expects to produce over 100 units per year from 2026.

This matters for the Middle East because the region's oil and gas operators have decades of experience commissioning, maintaining, and operating gas turbines — from offshore platforms to LNG export terminals. The operational discipline required to run a 48 MW aeroderivative turbine behind a hyperscale facility is remarkably similar to what energy megaproject teams have been doing for 30 years.

/pmo "The skills that kept LNG trains running at 99.5% availability are the same skills that hyperscale commissioning demands. The turbine doesn't care whether it's powering a compressor or a GPU cluster — it cares about fuel quality, vibration monitoring, and planned maintenance windows."

The Programme Management Challenge

Integrating gas turbines into hyperscale delivery is not simply a procurement exercise. It introduces a layer of programme complexity that most data centre developers have never managed: fuel supply agreements, emissions permitting, turbine commissioning sequences, and the interface between electrical infrastructure and IT load.

In a behind-the-meter configuration, the turbine package is not an isolated asset — it is the critical path. A two-month delay in turbine commissioning does not just push back a power milestone; it cascades into server deployment, network activation, and customer onboarding. In programmes measured in hundreds of millions of dollars, that cascade translates directly into revenue loss and contractual exposure.

This is where the discipline of energy megaproject programme management — earned-value tracking, integrated master scheduling, and independent commissioning assurance — becomes essential. Hyperscale delivery without this rigour is how 18-month programmes become 30-month programmes.

The Hive Platform

PMO Hive's heritage in energy megaprojects — LNG, offshore platforms, and critical national infrastructure — translates directly into hyperscale gas turbine integration. Our independent programme governance provides the schedule risk analysis, EPC oversight, and commissioning readiness assurance that turbine-backed hyperscale campuses require.

From oilfields to fibre fields, the control frameworks are the same. The stakes are just measured in rack capacity instead of barrels.